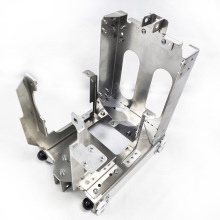

Custom stainless steel welding galvanized plate fabricate

| Unit Price: | 0.5~1.5 USD |

|---|---|

| Payment Type: | L/C,T/T,Paypal,Money Gram,MoneyGram,PayPal |

| Incoterm: | FOB,EXW,DDP,DDU,Express Delivery,CIP |

| Min. Order: | 1000 Piece/Pieces |

Basic Info

Brand: Custom

Shaping Mode: Plastic Injection Mould, Injection Moulding

Delivery Time: 30days

Brand Name: Fce

Cerifications: Iso9001, Iso14001, Iatf16949, Ohsms18001, Iso13485

2nd Process In House: Pad Printing, Screen Printing, Spray Painting, Assembly

Machine Tonnage: 35ton To 2000ton

Process: Insert Moulding, Imd/Iml, Multi-K, Gas Assistance

2nd Process Outsource: Electro-Plating, Plasma, Ed Etc.

Machine Type: Hydraulic, Vertical, Multi-K, Powder Injection

Material: Abs, Gpps, Hips, As, Ms, Pmma, Pc, Pa+Gf, Lcp Etc

Colour: Customized Compounded Resin To Pantone Code Or Colour Plaque

Place Of Origin: Jiangsu, China

Additional Info

Packaging: - Proper packing foam bag/sheet protect the part - Put the part on the PET tray - Pack the tray and products into carton box - Seal the carton box with tapes - Lay the boxes on the pallet with 8 corners protector - Band the box and pallet together - Seal

Productivity: 5000pcs/week

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 1000 Piece/Pieces per Week

Certificate: ISO9001

Port: Shanghai/Ningbo,Shenzhen

Payment Type: L/C,T/T,Paypal,Money Gram,MoneyGram,PayPal

Incoterm: FOB,EXW,DDP,DDU,Express Delivery,CIP

Product Description

Welding, is the process of joining two metals together by heating the metal surfaces up to their melting points. However, the process of welding isn’t as simple as it sounds. Welding is a highly technical process, with numerous types and techniques that only skilled personnel are able to understand and practice

Considerations for welding

l Heat: Different types of materials are also subject to distortion. Warping can also occur if the heat is too high

l Process selection: In order to avoid the usual problems that come with welding thin metal, you should carefully consider the process

l Equipment: need to consider the equipment that used and choose the right method to weld.

TIG (Tungsten Inert Gas) welding sheet metal is certainly one of the most common welding methods. This is an arc welding process wit

an infusible electrode, protected by inert gas (the gases most commonly used are argon or helium), which can be performed

with or without filler metal

What is the thinnest sheet metal that can be welded?

A welder should approach welding thin materials with caution. You should also take into account the type of material and the welding

process you are planning to implement. Gas metal arc welding (GMAW) is a very effective method in joining together thinner materials.

So, for instance, you can work on 18-ga. to 0.1875-in. stainless steel or 24-ga. to 0.1875-in. carbon steel.

How do you stop a weld distortion?

Sometimes when welding sheet metal, distortion can occur due to the thickness of the material. Even something minimal likes to patch a

panel can end up with devastating effects. The best way to prevent this is to avoid creating distortion as much as possible.

Some methods include:

Size of weld: Avoid overwhelming when making a weld seam.

Intermittent welding: Try making breaks instead of a single long weld.

Fewer weld passes: The more weld passes a welder makes the greater the chance of shrinking the materials. Try making less.

Welding placement: You should weld near the neutral axis or the center or the part.

Backset welding: A welder should weld from left to right, placing every weld seam from left to right rather than the opposite way.

Preset parts: Make trial welds before you start the process by setting the parts together.

Use clamps: Clamps are a good way to use instead of a tack weld. You simply clamp down the parts and set them in the desired way

before you start welding.

Thermal stress relief: The process involves controlled heating of the weldment followed by controlled colling afterward.

Minimize welding time: The more time you take to weld a panel the greater the chances are of creating distortion. Simply try

shortening the time needed to weld.

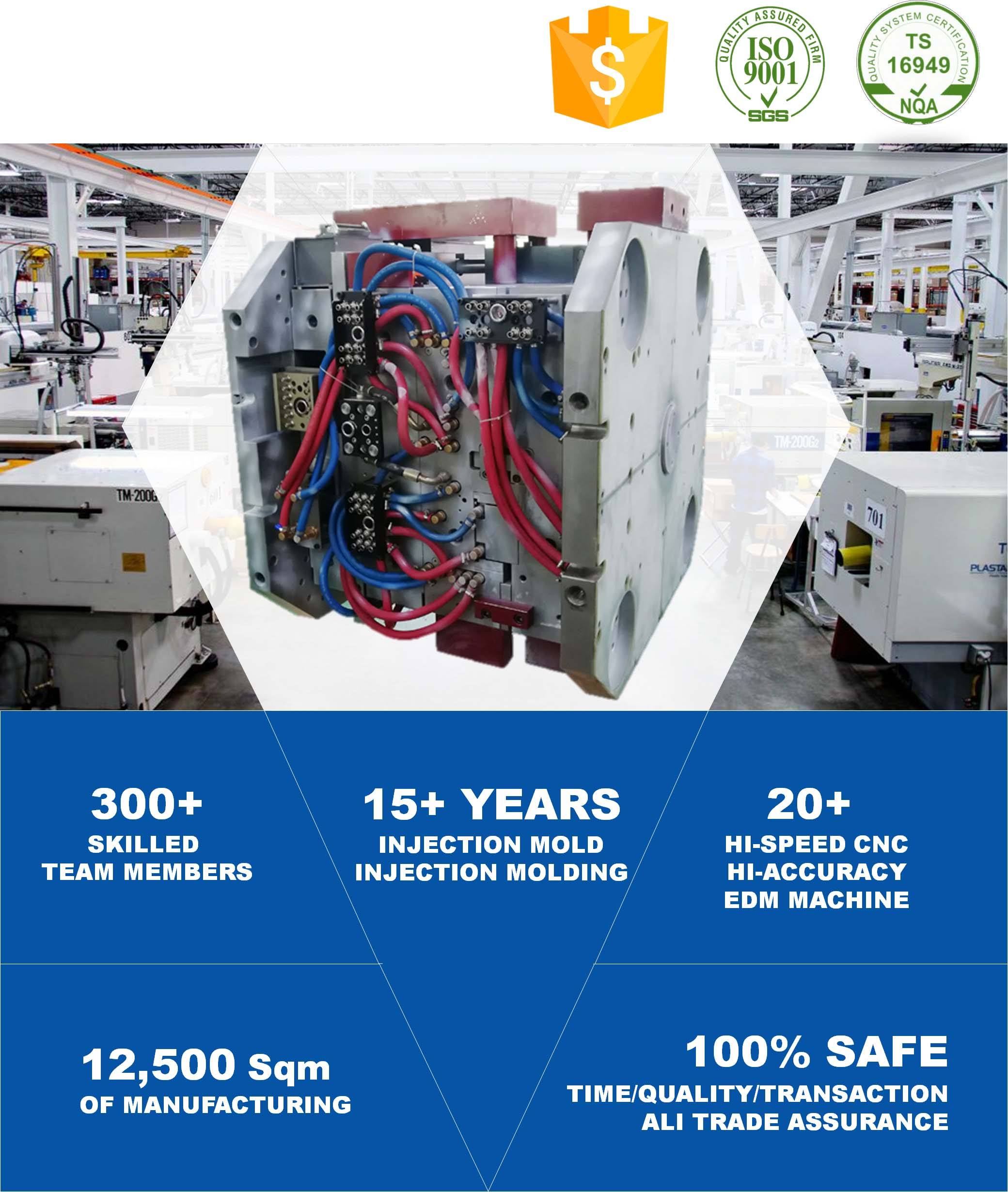

Precision Injection Molding and Sheet metal are our core businesses. Delivering injection molding and contract manufacturing in the packaging, consumer appliances, home automation, and automotive sectors etc.

When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

| COMPANY NAME | Suzhou FCE Precision Electronics Co.,Ltd |

| BUSINESS TYPE | Manufacturer |

| MAIN PRODUCTS | Plastic Injection Mold, Prototype tool, Injection Molding Parts, Metal Stamping Die, Stamping Processing for Auto, Consumer Electronics, Appliance, Medical, Houseware… |

| CERTIFICATES | ISO 9001, IATF16949 |

| QAULITY POLICY | Customer-centric, Action concurrent with words |

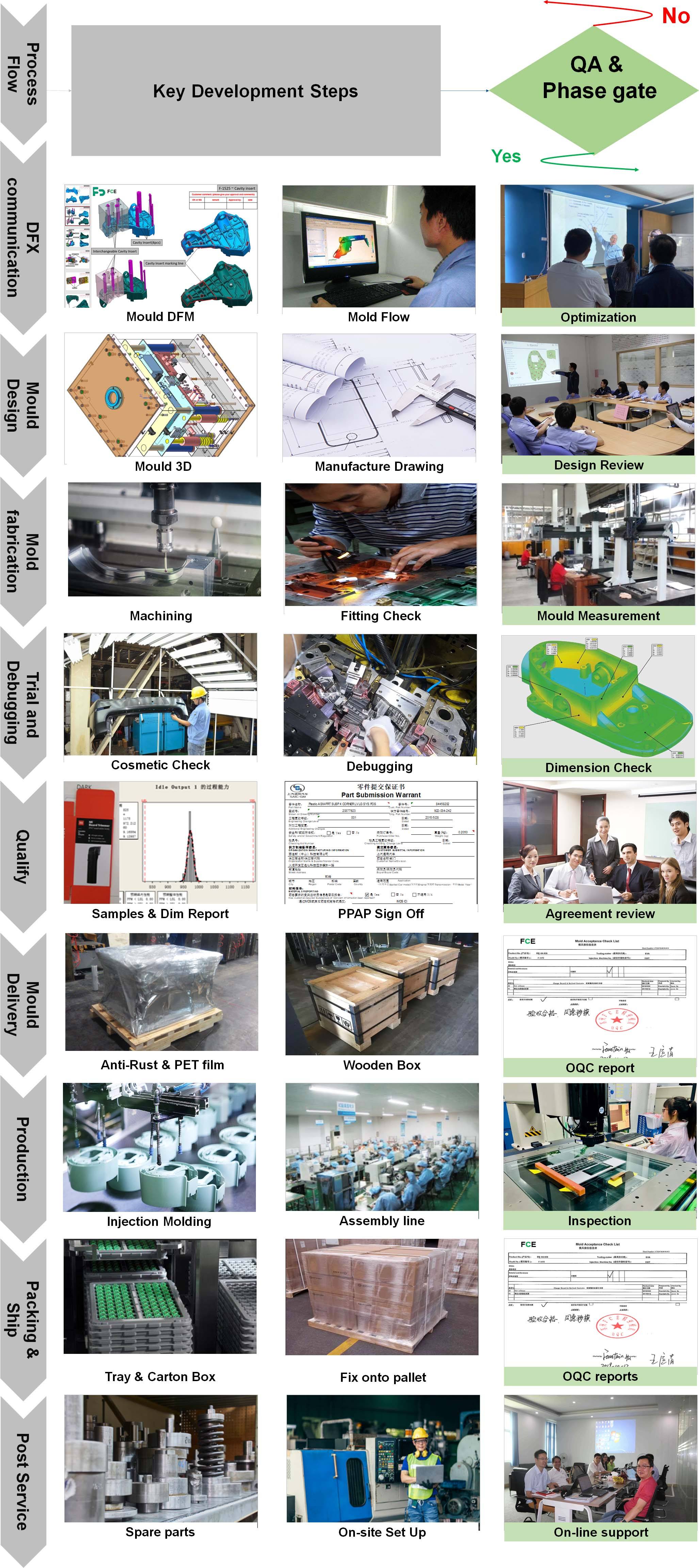

1. Consulting 2. Engineering 3. Prototyping 4. Manufacturing

All in ONE

Where the Good Quality from: Good Quality Planning, Project Management, Work Procedure, Traceability all in our Blood

High precision injection moulding and Sheet Metal are at our core; delivering contract manufacturing in the packaging, consumer appliances, business machines, home automation, life science and automotive sectors. When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

FCE has provided industry-leading injection Molding Services, and we have continued to develop and invest in cutting-edge technologies. Whatever your goals for your component or product, we have the expertise and equipment to deliver. Our specialist capabilities include in-mould labelling and decoration, Multi-k Injection Moulding, liquid silicone rubber, Sheet Metal Processing, Custom Machining, clean room production and more. And because of our global reach, we can cost-effectively source materials and tailored solutions, from concept to reality.

We use our project management skill to create a structured phase-gate process. This establishes your goals and expectations and ensures that you have the oversight and impetus to reach a positive outcome.

The injection Molding, metal stamping, sheet metal processing, machining factories are certificated by ISO 9001, IATF16949. Silicone Molding and Injection molding certificated by ISO13485

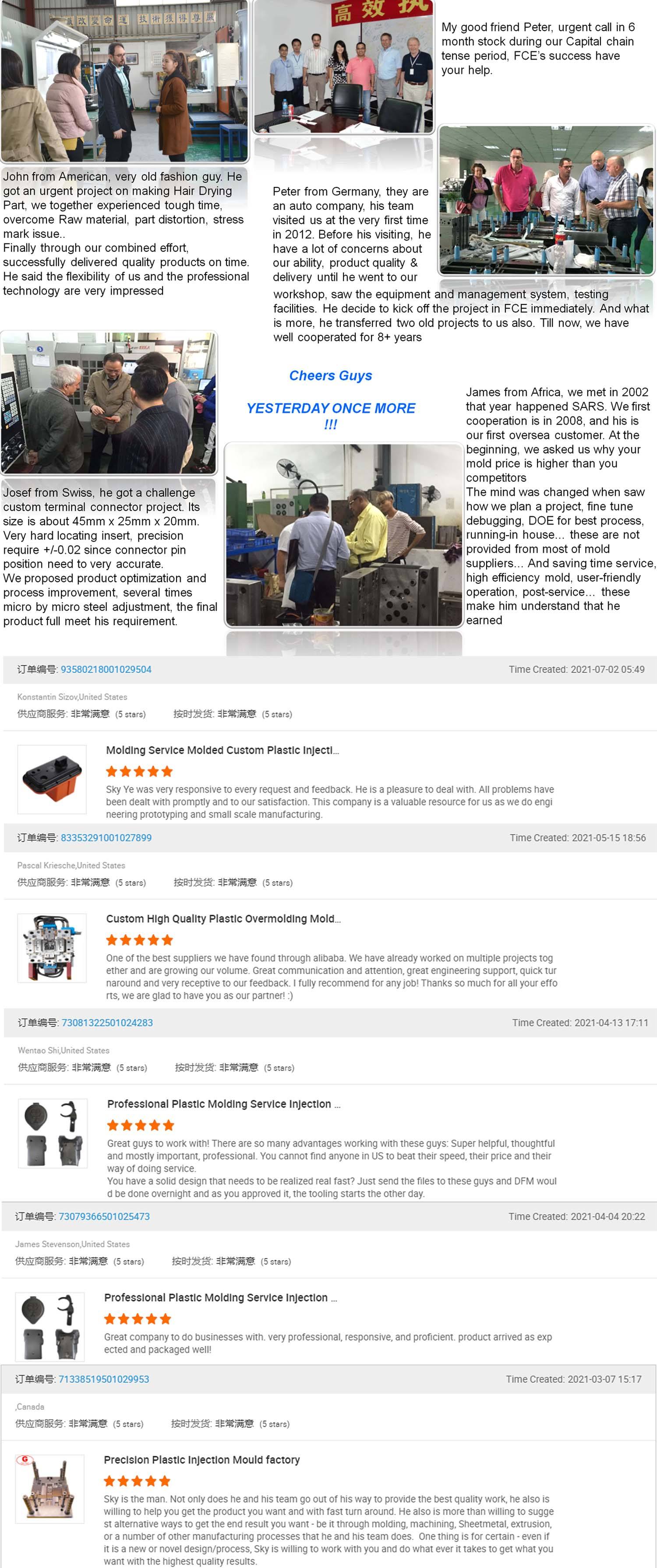

Q1.How can I get a Quotation?

1) 3D with stp.(preferred) igs, stl.prt. format

2) 2D drawing for tolerance/material/surface finish/test requirement/regulations

3) Quantity (by order, month and a Year)

We can help you to complete above for ODM project

Q2.How do you ensure product quality?

As you can see above, we apply assessment, planning, monitor at every single process. Some bullet points:

Q3. How do you ensure on time delivery?

1) Detailed planning, details to per hour/person/machine number/stakeholder…

2) Main material driving management system

3) Daily progress meeting, a recovery plan will be reviewed by management team once any key chain is delay.

4) If delay happen on delivery, FCE will provide customer 1% discount for one week delay, up limit to 10%

Q4. What is your defective part handling process

FCE have good traceability record for people/machine/parameter/material batch/inspection, that will help quick quarantine defect parts, find out root cause and apply prevention method

Product Categories : Sheet Metal Fabrication > Sheet Metal Fabrication Service