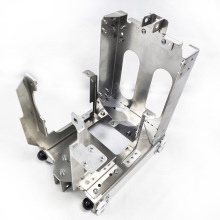

precision sheet metal fabrication

| Payment Type: | L/C,T/T,MoneyGram,PayPal |

|---|---|

| Min. Order: | 1 Set/Sets |

Basic Info

Place Of Origin: China

Brand Name: Fce

Material: Stainless Steel,AL

Process: Stamping

Surface Treatment: Powder Coated

Product Name: Sheet Metal Fabrication Stamping Bending Welding Turnning Parts

Additional Info

Packaging: 1-Surface coated with anticorrosive paint 2-Wrapped with PE film 3-Fix the tool into wooden box by screw and customized tool 4- hydraulic cylinder is protected by customized bracket 5- Print basic goods information outside box

Transportation: Express,Ocean,Land,Air

Supply Ability: 50000 Set/Sets per Month

Port: Shanghai/Ningbo

Payment Type: L/C,T/T,MoneyGram,PayPal

Product Description

1, Sheet Metal Processing is actually metal products processing, it is more to the metal plate to be transformed, so as to achieve their use in many different places. Its processing methods include many, stamping, cutting, cutting and other ways to change the performance and shape of the metal. Using this processing technology can bring a lot of convenience to people's life, but also promote the development of China's machinery manufacturing industry. For the sheet metal processing industry, it can be used in a number of insights.

2, there are many products around us through sheet metal processing to realize their use value. Such as doors and stainless-steel Windows that are used in every home. There are electrical chassis, various control boxes, etc., need to be completed by sheet metal processing. In addition, sheet metal processing is now moving in the direction of large-scale development, such as the automobile manufacturing industry and shipping industry as well as a variety of large mechanical processing factories will use sheet metal processing this advanced and efficient technology.

3. For the sheet metal processing industry. Their development prospects are bright, can be used more in the future, with the development of the economy and the continuous progress of the machinery manufacturing industry. It is also in increasing demand. At the present stage, what sheet metal processing industry needs to do is to constantly improve its own technical level, increase innovation ability, strive to introduce advanced production equipment, expand the scale of production.

4. As far as sheet metal processing industry is concerned, it is more important to realize the standardization and institutionalization of operation, with strict development planning and feasible development programs. Strive to create their own sheet metal brand, do not rely too much on the label of foreign brands, so that for their own development is very unfavorable. If you want to get real development, you must continuously start your own brand and achieve large-scale development.

| Material | Aluminum, stainless steel, copper, brass, galvinized etc. |

| Size | Customized |

| Surface treatment | Powder Coating, eletroplating, oxide,anodization |

| Technics | laser cut, bend, weld, stamp |

| Sample | Need to pay sample fee |

| Certification | ISO9001:2015 |

| OEM | Accept |

| Drawing Format | 3D/CAD/Dwg/IGS/STP |

| Color | Customized |

| Application | Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

Custom Machining, Injection Molding, Laser Cutting, Molding Services, Multi-k Injection Moulding, Plastic Injection, Powder Coating, Sheet Metal Processing

Product Categories : Sheet Metal Fabrication > Sheet Metal Fabrication Service