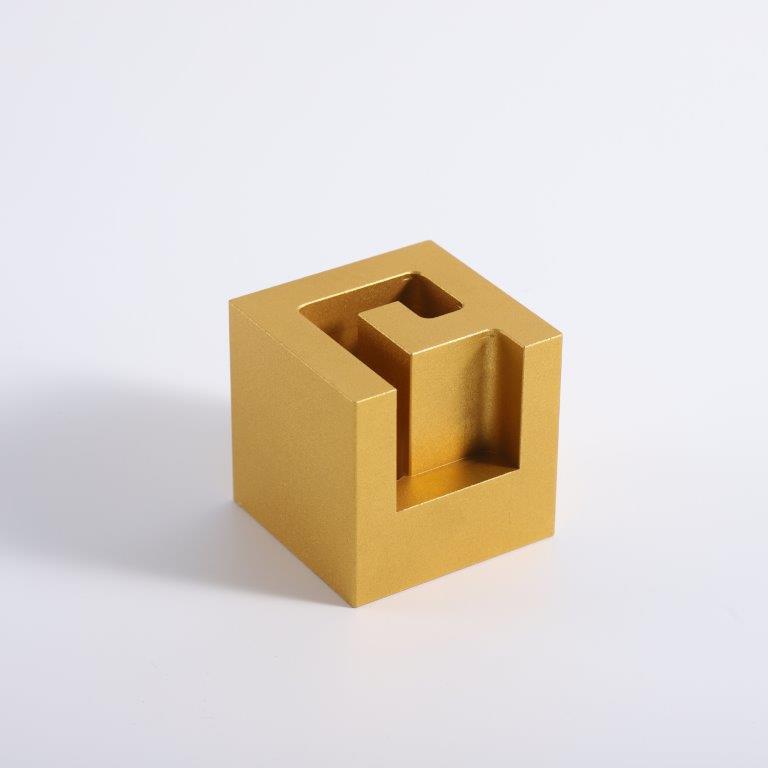

High precision professional hot machining part

| Unit Price: | 1~5 USD |

|---|---|

| Payment Type: | Western Union,T/T,Paypal,L/C,Money Gram,MoneyGram |

| Incoterm: | FOB,EXW,CIP,Express Delivery,DDP,DDU |

| Min. Order: | 1 Piece/Pieces |

Basic Info

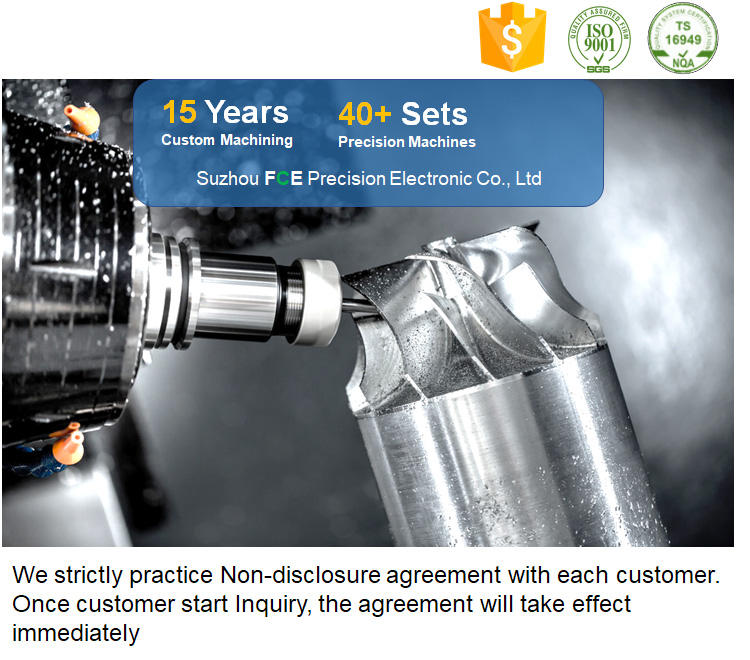

Brand: FCE

Types Of: Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Turning, Wire Edm, Other Machining Services, Rapid Prototyping

Machinable Materials: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Model Number: Oem

Micro Machining Or Not: Micro Machining

CNC Machining Or Not: Cnc Machining

Type: Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire Edm, Rapid Prototyping

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Brand Name: FCE

Tolerance: ±0.01mm

Surface Treatment: anodizing/polishing/plating/painting

Service: packaging Assembly services

Certification: ISO9001/TS16949/QS/ISO14001

Logo: Accept Custom Logo

Oem/odm: OEM ODM CNC Machining Service

Lead Time: 10-20 Days

Product Name: CNC Mchining Parts

Place Of Origin: Jiangsu, China

Additional Info

Packaging: Plastic molds packing methods: 1-Surface coated with anticorrosive paint 2-Wrapped with PE film 3-Fixed and sealed by wooden boxes

Productivity: 1000pcs/week

Transportation: Express,Ocean,Land,Air

Place of Origin: Jiangsu

Supply Ability: 50 Set/Sets per Month

Certificate: ISO9001 IATF16949

Port: Shanghai/Ningbo/Shenzhen

Payment Type: Western Union,T/T,Paypal,L/C,Money Gram,MoneyGram

Incoterm: FOB,EXW,CIP,Express Delivery,DDP,DDU

Product Description

CNC Turning is the process of remove material from a rotating workpiece using the linear path of tools on a CNC lathe. In a simple perspective, the main elements involved in this process are the rotating spindle in which your work part is clamped and the cutting tool that is mounted on a turret.

Advantages:

Accuracy

For many companies, the accuracy of CNC turning is one of their most competitive advantages. By incorporating CAD or CAM files into the process, the machine can perform rigorous measurements and eliminate the waste of natural human error. Using advanced machines, experts can provide extremely high accuracy, whether it is to produce prototypes or complete the entire production process. Especially when accuracy is critical, a small defect or a slight deviation from the tolerance is enough to cause serious damage. Since the machine used is programmed, every cut is perfect. In other words, the last component completed in the production run is the same as the first component.

Flexibility

Flexibility is another benefit of precision turning services. They have multiple size functions to meet the flexibility of your various applications. Since the tasks performed by this machine are programmed, the change is relatively simple. By accessing the keyboard, the operator of the machine can complete a component for your company and then make the appropriate programming changes to produce something completely different. Therefore, you can rely on the same manufacturing company or precision CNC Machining Service provider to provide a large number of unique parts.

Repeatability

By producing batches of unparalleled accuracy, CNC turning can provide excellent repeatability. In this way, your business can maximize output and reduce losses, which allows you to freely invest capital elsewhere.

Safety

The fact is that the operators who supervise the lathe must receive extensive training. After all, an environment with tools and machinery may pose a risk of personal injury or even more serious. To ensure 100% safety, the manufacturing company you choose will follow strict rules and regulations. The turning machine is automatic, which means that the operator is present but not on the machine, which can reduce labor intensity. At the same time, the lathe body adopts a fully enclosed or semi-enclosed protective device to prevent flying debris from the processed product and reduce the damage to the staff.

Faster Results

When using CNC lathes to perform tasks indicated by programming, there is less risk of errors. Therefore, this machine can complete production faster without affecting the quality of the finished product. In the end, you can finally get the parts or components needed by the industry faster than other solutions.

Most defects in turning are inaccuracies in a feature's dimensions or surface roughness. There are several possible causes for these defects, including the following:

Possible Defects:

Incorrect cutting parameters - If the cutting parameters such as the feed rate, spindle speed, or depth of cut are too high, the surface of the workpiece will be rougher than desired and may contain scratch marks or even burn marks. Also, a large depth of cut may result in vibration of the tool and cause inaccuracies in the cut.

Dull cutting tool - As a tool is used, the sharp edge will wear down and become dull. A dull tool is less capable of making precision cuts.

Unsecured workpiece - If the workpiece is not securely clamped in the fixture, the friction of turning may cause it to shift and alter the desired cuts.

| Material Available | | | | | | |||||

| Aluminum | Stainless Steel | Brass | Copper | Plastic | Iron | |||||

| AL6061 | SS201 | C35600 | C11000 | POM | 20# | |||||

| AL6063 | SS301 | C36000 | C12000 | Peek | 45# | |||||

| AL6082 | SS303 | C37700 | C12200 | PMMA | Q235 | |||||

| AL7075 | SS304 | C37000 | C10100 | ABS | Q345B | |||||

| AL2024 | SS316 | C37100 | … | Delrin | Q345B | |||||

| AL5052 | SS416 | C28000 | | Nylon | 1214/1215 | |||||

| etc | etc | C26000 | | PVC | 12L14 | |||||

| … | … | C24000 | | PP | Carbon steel | |||||

| | | ... | | ... | | |||||

| Surface Treatment | | | | | | |||||

| As machined | | All metals | | | | |||||

| Polished | | All metals+Plastic (e.g aluminum, steel,nylon, ABS) | | | | |||||

| Powder Coated | | All metals ( e.g aluminum, steel) | | | | |||||

| Brushing | | All metals (e.g aluminum, steel) | | | | |||||

| Anodized | | Aluminum and Titanium alloys | | | | |||||

| Electroplated | | All Metals + plastic (ABS, PC/ABS) | | | | |||||

| Bead Blasted | | Steel and Aluminum and Titanium alloys | | | | |||||

| Anodized Clear or Color | | Aluminum and Titanium alloys | | | | |||||

Professional to make all kinds of metal parts, like CNC cutting& milling parts, stamping parts, metal sheet parts, assembly unit etc. Our Products cover automotive, Electronic, medical, air, home & office appliance industry.

We are certificated by ISO 9001 and IATF 16949.

Product Categories : Machining Service > CNC Turning