Custom precision CNC turning machined aluminum parts

| Unit Price: | 1~5 USD |

|---|---|

| Payment Type: | Western Union,T/T,Paypal,L/C,Money Gram,MoneyGram |

| Incoterm: | FOB,EXW,CIP,Express Delivery,DDP,DDU |

| Min. Order: | 1 Piece/Pieces |

Basic Info

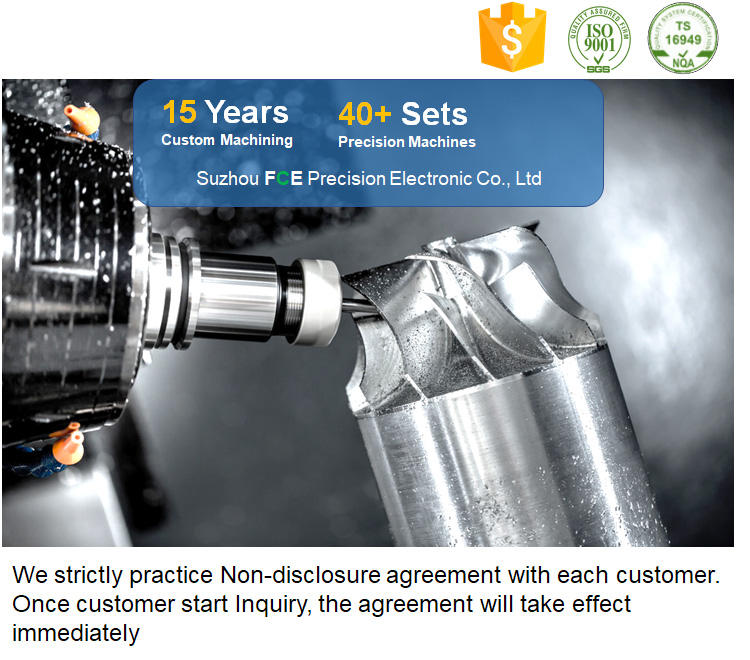

Brand: FCE

Types Of: Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Turning, Wire Edm

Machinable Materials: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Model Number: Oem

Micro Machining Or Not: Micro Machining

CNC Machining Or Not: Cnc Machining

Type: Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire Edm, Rapid Prototyping

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Brand Name: FCE

Tolerance: ±0.01mm

Surface Treatment: anodizing/polishing/plating/painting

Service: packaging Assembly services

Certification: ISO9001/TS16949/QS/ISO14001

Logo: Accept Custom Logo

Oem/odm: OEM ODM CNC Machining Service

Lead Time: 10-20 Days

Product Name: CNC Mchining Parts

Place Of Origin: Jiangsu, China

Whether CNC Machining: Cnc Machining

Whether Micro Processing: Micro Machining

Place Of Origin: China

Additional Info

Packaging: Plastic molds packing methods: 1-Surface coated with anticorrosive paint 2-Wrapped with PE film 3-Fixed and sealed by wooden boxes

Productivity: 1000pcs/week

Transportation: Express,Ocean,Land,Air

Place of Origin: Jiangsu

Supply Ability: 50 Set/Sets per Month

Certificate: ISO9001 IATF16949

Port: Shanghai/Ningbo/Shenzhen

Payment Type: Western Union,T/T,Paypal,L/C,Money Gram,MoneyGram

Incoterm: FOB,EXW,CIP,Express Delivery,DDP,DDU

Product Description

Turning is a subtractive machining process that uses a cutting tool to remove material for creating cylindrical parts. The tool itself moves along the axis of the machined part while the part is rotating, creating a helical toolpath.

The term turning refers to producing parts by cutting operations on the external surface. The opposite of turning is boring, whereby lathe machines are used for creating hollow parts.

Turning is used to produce rotational, typically axi-symmetric, parts that have many features, such as holes, grooves, threads, tapers, various diameter steps, and even contoured surfaces. Parts that are fabricated completely through turning often include components that are used in limited quantities, perhaps for prototypes, such as custom designed shafts and fasteners. Turning is also commonly used as a secondary process to add or refine features on parts that were manufactured using a different process. Due to the high tolerances and surface finishes that turning can offer, it is ideal for adding precision rotational features to a part whose basic shape has already been formed.

Typical Feasible Shapes: Thin-walled: Cylindrical

Solid: Cylindrical

Part size: Diameter: 0.02 - 80 in Materials: Metals

Alloy Steel

Carbon Steel

Cast Iron

Stainless Steel

Aluminum

Copper

Magnesium

Zinc

Ceramics

Composites

Lead

Nickel

Tin

Titanium

Elastomer

Thermoplastics

Thermosets

Surface finish - Ra: 16 - 125 μin 2 - 250 μin Tolerance: ± 0.001 in. ± 0.0002 in. Max wall thickness: 0.02 - 2.5 in. 0.02 - 80 in. Quantity: 1 - 1000 1 - 1000000 Lead time: Days Hours Advantages: All materials compatible

Very good tolerances

Short lead times Disadvantages: Limited to rotational parts

Part may require several operations and machines

High equipment cost

Significant tool wear

Large amount of scrap Applications: Machine components, shafts, engine components

| Material Available | | | | | | |||||

| Aluminum | Stainless Steel | Brass | Copper | Plastic | Iron | |||||

| AL6061 | SS201 | C35600 | C11000 | POM | 20# | |||||

| AL6063 | SS301 | C36000 | C12000 | Peek | 45# | |||||

| AL6082 | SS303 | C37700 | C12200 | PMMA | Q235 | |||||

| AL7075 | SS304 | C37000 | C10100 | ABS | Q345B | |||||

| AL2024 | SS316 | C37100 | … | Delrin | Q345B | |||||

| AL5052 | SS416 | C28000 | | Nylon | 1214/1215 | |||||

| etc | etc | C26000 | | PVC | 12L14 | |||||

| … | … | C24000 | | PP | Carbon steel | |||||

| | | ... | | ... | | |||||

| Surface Treatment | | | | | | |||||

| As machined | | All metals | | | | |||||

| Polished | | All metals+Plastic (e.g aluminum, steel,nylon, ABS) | | | | |||||

| Powder Coated | | All metals ( e.g aluminum, steel) | | | | |||||

| Brushing | | All metals (e.g aluminum, steel) | | | | |||||

| Anodized | | Aluminum and Titanium alloys | | | | |||||

| Electroplated | | All Metals + plastic (ABS, PC/ABS) | | | | |||||

| Bead Blasted | | Steel and Aluminum and Titanium alloys | | | | |||||

| Anodized Clear or Color | | Aluminum and Titanium alloys | | | | |||||

Professional to make all kinds of metal parts, like CNC cutting& milling parts, stamping parts, metal sheet parts, assembly unit etc. Our Products cover automotive, Electronic, medical, air, home & office appliance industry.

We are certificated by ISO 9001 and IATF 16949.

Product Categories : Machining Service > CNC Turning