Silicon rubber molding 3D printing

| Unit Price: | 1~100 USD |

|---|---|

| Payment Type: | Western Union,T/T,Paypal,L/C,Money Gram,MoneyGram |

| Incoterm: | FOB,CIF,EXW,CIP,DDP,DDU,Express Delivery |

| Min. Order: | 1 Piece/Pieces |

Basic Info

Brand: FCE

Model Number: Oem

Micro Machining Or Not: Micro Machining

CNC Machining Or Not: Cnc Machining

Type: Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire Edm, Rapid Prototyping

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Brand Name: FCE

Product Name: 3D Printing Service

Tolerance: ±0.01mm

Surface Treatment: anodizing/polishing/plating/painting

Service: packaging Assembly services

Certification: ISO9001/TS16949/QS/ISO14001

Logo: Accept Custom Logo

Oem/odm: OEM ODM CNC Machining Service

Lead Time: 10-20 Days

Place Of Origin: Jiangsu, China

Additional Info

Packaging: Plastic molds packing methods: 1-Surface coated with anticorrosive paint 2-Wrapped with PE film 3-Fixed and sealed by wooden boxes

Productivity: 10000pcs/week

Transportation: Ocean,Land,Air,Express

Place of Origin: JiangSu

Supply Ability: 50 Set/Sets per Month

Certificate: ISO9001 IATF16949

Port: Shanghai/Ningbo/Shenzhen

Payment Type: Western Union,T/T,Paypal,L/C,Money Gram,MoneyGram

Incoterm: FOB,CIF,EXW,CIP,DDP,DDU,Express Delivery

Product Description

Silicone Overmolding can be conducted through two methods, multi-shot molding or Insert Molding. When it comes to double shot molding, the first material to go in is the substrate and the second is the overmold. This process involves a press that has multiple barrels that shoot two types of resins into the same Injection Molding tool. This whole process involves a single machine that is constantly moving. However, the double shot method is preferred when you have large units of parts because it requires expensive machinery and molds.

Overmolding is not without its limitations. Several factors must be weighed before determining if it is the best solution as below:

One main consideration is that the two materials must be compatible, chemically and thermally.

Since we have to put the first piece into the injection molding for overmolding, the first parts have to withstand the temperature needed to melt the second material.

The wall thickness of the substrate and overmold should be as uniform as possible to obtain the best molding cycle time. Wall thickness between 1.5MM to 3MM generally provide the best bonding.

Keeping 0.5MM minimum in corners reduces localized stresses.

For the thick TPE sections, cored out to minimize shrinkage problems, reduce the part weight and lower cycle time.

Avoid deep or un-ventable blind pockets or ribs in your design.

Transitions between wall thickness should be gradual to reduce flow problems, such as back fills and gas traps.

The TPE/TPU/TPV should be less thick than the substrate to prevent warpage, especially critical for long, flat geometries.

Design in a mechanical interlock when possible

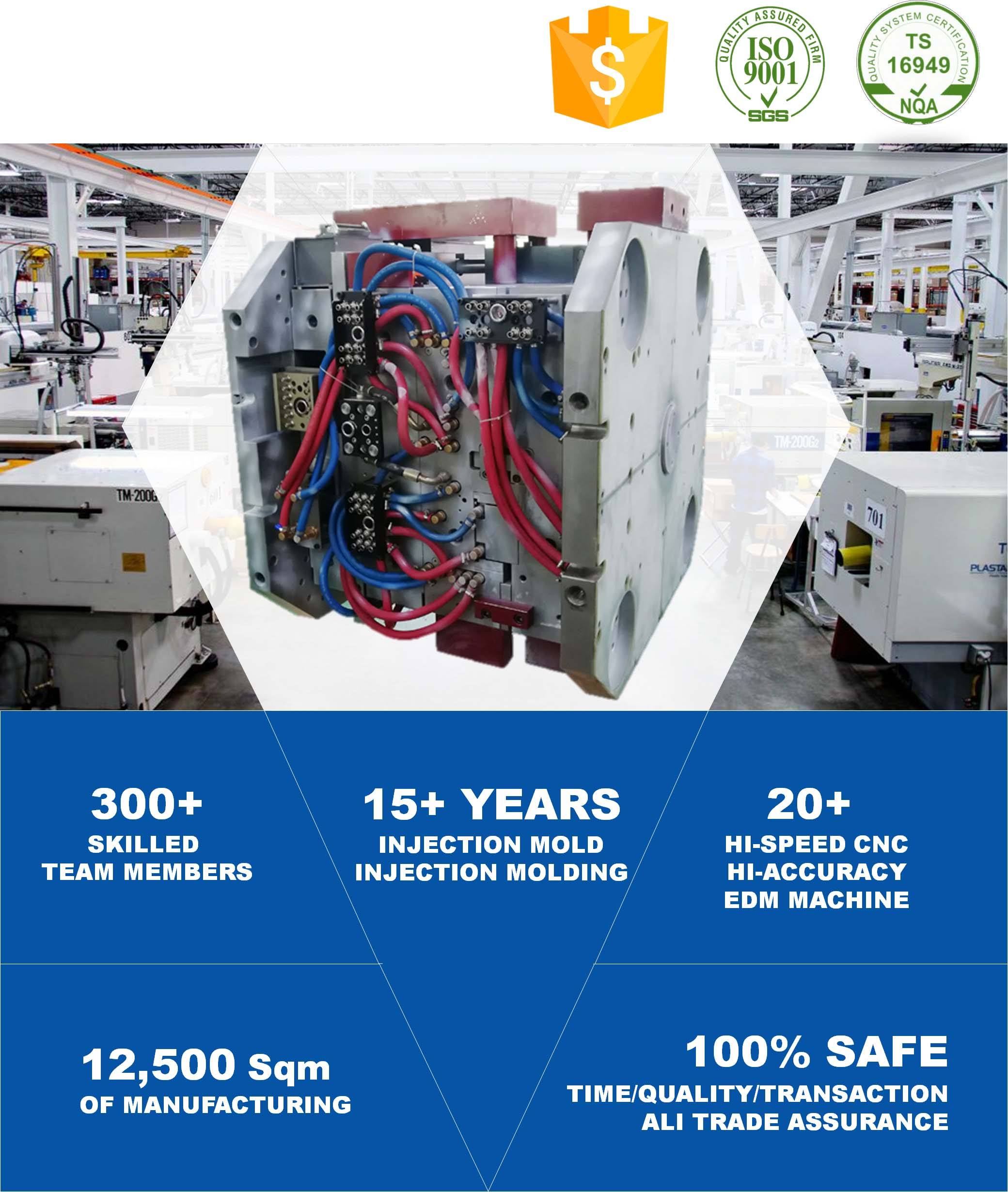

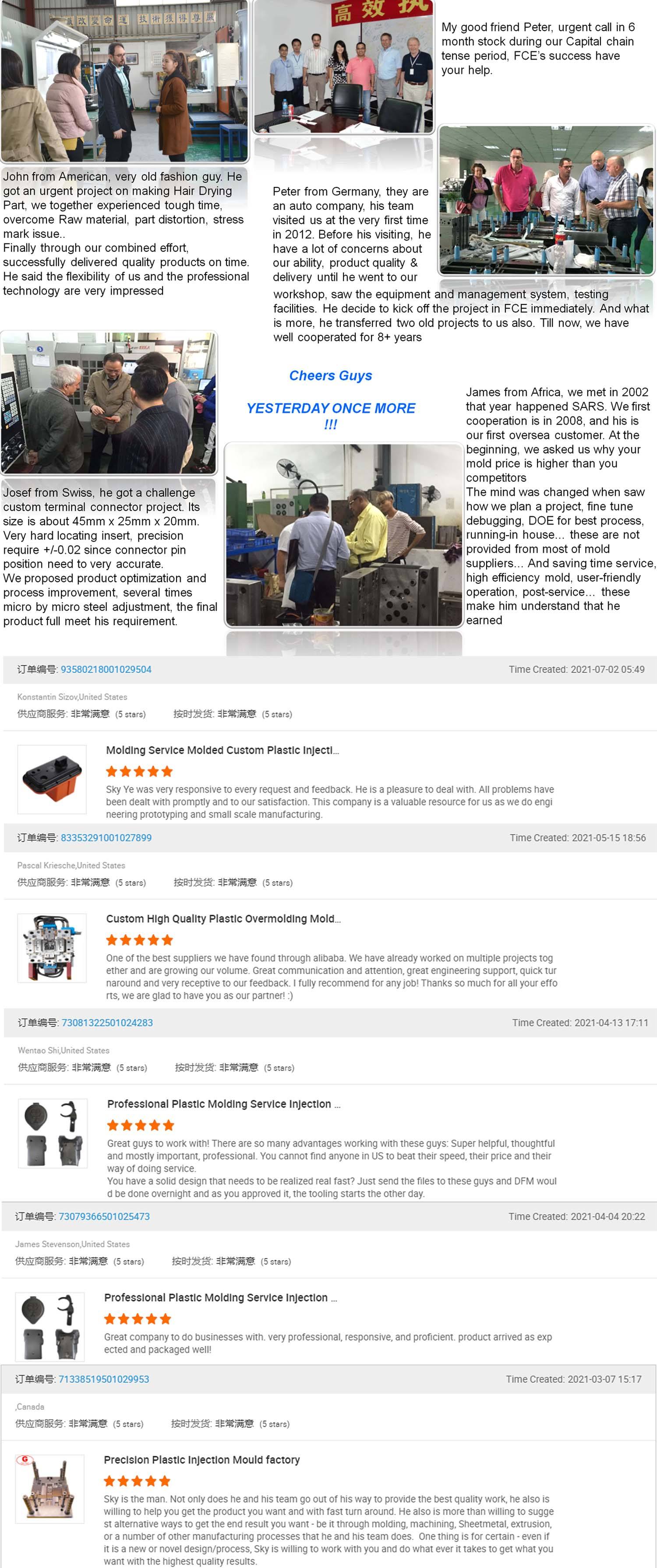

Precision Injection Molding and Sheet metal are our core businesses. Delivering injection molding and contract manufacturing in the packaging, consumer appliances, home automation, and automotive sectors etc.

When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

| COMPANY NAME | Suzhou FCE Precision Electronics Co.,Ltd |

| BUSINESS TYPE | Manufacturer |

| MAIN PRODUCTS | Plastic Injection Mold, Prototype tool, Injection Molding Parts, Metal Stamping Die, Stamping Processing for Auto, Consumer Electronics, Appliance, Medical, Houseware… |

| CERTIFICATES | ISO 9001, IATF16949 |

| QAULITY POLICY | Customer-centric, Action concurrent with words |

1. Consulting 2. Engineering 3. Prototyping 4. Manufacturing

All in ONE

Where the Good Quality from:

Good Quality Planning, Project Management, Work Procedure, Tracibility

All in our Blood

High precision injection moulding and Sheet Metal are at our core; delivering contract manufacturing in the packaging, consumer appliances, business machines, home automation, life science and automotive sectors. When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

FCE has provided industry-leading injection Molding Services, and we have continued to develop and invest in cutting-edge technologies. Whatever your goals for your component or product, we have the expertise and equipment to deliver. Our specialist capabilities include in-mould labelling and decoration, Multi-k Injection Moulding, liquid silicone rubber, Sheet Metal Processing, Custom Machining, clean room production and more. And because of our global reach, we can cost-effectively source materials and tailored solutions, from concept to reality.

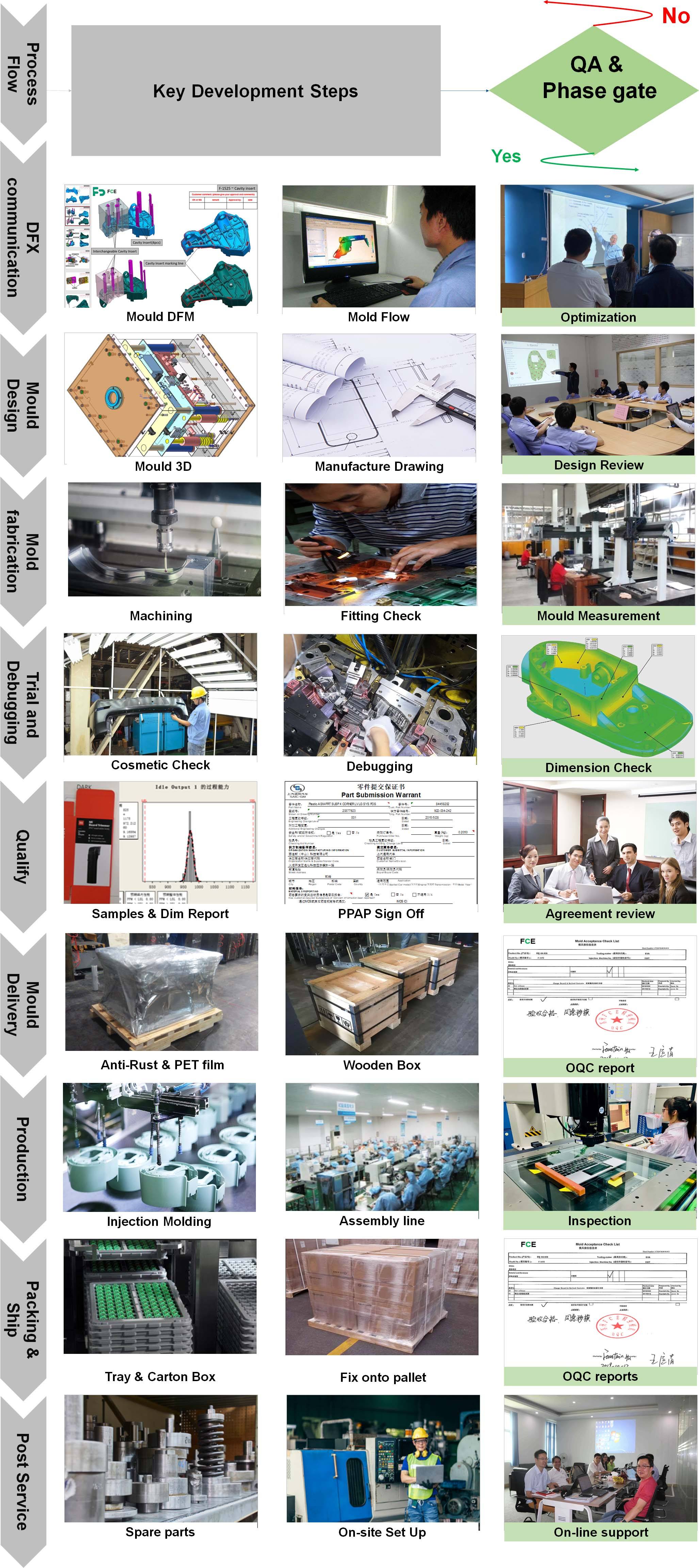

We use our project management skill to create a structured phase-gate process. This establishes your goals and expectations and ensures that you have the oversight and impetus to reach a positive outcome.

The injection Molding, metal stamping, sheet metal processing, machining factories are ceritificated by ISO 9001, IATF16949. Silicone Molding and Injection molding certificated by ISO13485

Q1.How can I get a Quotation?

1) 3D with stp.(preferred) igs, st.prt. format

2) 2D drawing for tolerance/material/surface finish/test requirement/regulations

3) Quantity (by order, month and a Year)

We can helpyoucomplete above for ODM project

Q2.How do you ensure product quality?

As you can see above, we apply assessment, planning, monitor at every single process. Some bullet points:

Q3. How do you ensure on time delivery?

1) Detailed planning, details to per hour/person/machine number/stakeholder…

2) Main material driving management system

3) Daily progress meeting, a recovery plan will be reviewed by management team once any key chain is delay.

4) If delay happen on delivery, Goutech will provide customer 1% discount for one week delay, up limit to 10%

Q4. What is your defective part handling process

Goutech have good traceability record for people/machine/parameter/material batch/inspection, that will help quick quarantine defect parts, find out root cause and apply prevention method

Product Categories : Rubber Moulding > Silicone Overmolding