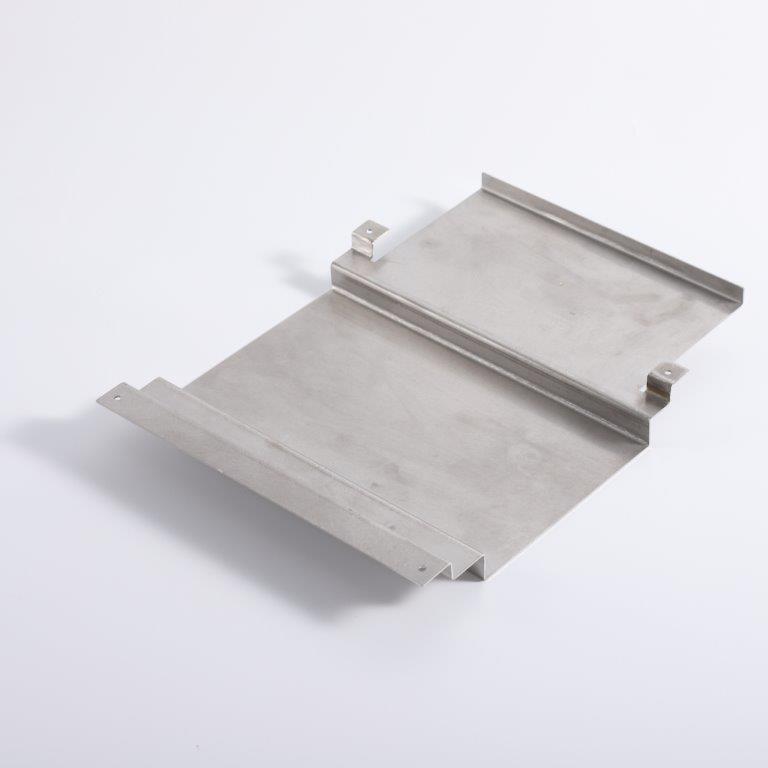

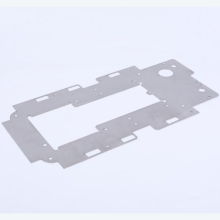

Custom high quality sheet metal aluminum stamping

| Unit Price: | 1~3 USD |

|---|---|

| Payment Type: | L/C,T/T,Paypal,Money Gram,MoneyGram,PayPal |

| Incoterm: | FOB,EXW,DDP,DDU,Express Delivery,CIP |

| Min. Order: | 1000 Piece/Pieces |

Basic Info

Brand: Custom

Shaping Mode: Plastic Injection Mould, Injection Moulding

Delivery Time: 30days

Brand Name: Fce

Cerifications: Iso9001, Iso14001, Iatf16949, Ohsms18001, Iso13485

2nd Process In House: Pad Printing, Screen Printing, Spray Painting, Assembly

Machine Tonnage: 35ton To 2000ton

Process: Insert Moulding, Imd/Iml, Multi-K, Gas Assistance

2nd Process Outsource: Electro-Plating, Plasma, Ed Etc.

Machine Type: Hydraulic, Vertical, Multi-K, Powder Injection

Material: Abs, Gpps, Hips, As, Ms, Pmma, Pc, Pa+Gf, Lcp Etc

Colour: Customized Compounded Resin To Pantone Code Or Colour Plaque

Place Of Origin: Jiangsu, China

Additional Info

Packaging: - Proper packing foam bag/sheet protect the part - Put the part on the PET tray - Pack the tray and products into carton box - Seal the carton box with tapes - Lay the boxes on the pallet with 8 corners protector - Band the box and pallet together - Seal

Productivity: 5000pcs/week

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 1000 Piece/Pieces per Week

Certificate: ISO9001

Port: Shanghai/Ningbo,Shenzhen

Payment Type: L/C,T/T,Paypal,Money Gram,MoneyGram,PayPal

Incoterm: FOB,EXW,DDP,DDU,Express Delivery,CIP

Product Description

Stamping dies are the tools that shape and cut sheet metal parts. They are commonly developed using computer-aided design (CAD) software and analytical programs to create and prove-out highly accurate, unambiguous designs. These designs are then translated into stamping dies by skilled craftsmen, known as diemakers. Once these stamping dies are mounted into presses, sheet metal is fed to them to produce parts.

Materials

Though virtually any metal, including gold, can be stamped, sheet metal is by far the most common. The type of metal used depends on the type of part that’s needed and its desired properties, such as corrosion- and heat-resistance.

Sheet metal stamping can produce parts from the following materials:

- Stainless steel

- Low- and high-carbon steel

- Aluminum

- Titanium

- Brass

- Bronze

- Copper

- Inconel

- Nickel alloys

Benefits of Using an Optimized Sheet Metal Design

The benefits of careful design optimization include:

Improved Cost to Useful Life Ratio. A well-optimized design will give you the best bang for your buck possible by making sure that the sheet metal form you order lasts for a long time without costing you too much. Using the wrong material can cause a custom metal form to wear out quickly. When your parts last for years or decades rather than months, you save money on constant re-orders.

Better Performance. Sometimes, an existing design could be greatly improved with just a few minor tweaks. For example, adding a removable side panel to materials handling basket can make unloading materials faster, saving on labor. Adding more supports to a shelf design can increase its ability to handle heavy loads.

Faster Delivery. By testing metal fabrication designs virtually, you can be spared the lengthy and expensive process of building, shipping, and testing multiple physical prototypes. If a design doesn’t pass the Autodesk simulation, it goes back to the drawing board to be reworked in a way that addresses the cause of the failure. This way, you know you’ll be getting a custom metal form that will meet or exceed your needs the first time, not after months and months of painstakingly slow tests.

Product Categories : Sheet Metal Fabrication > Sheet Metal Stamping