Quick 3d printing service Rrapid prototyping molding service

| Payment Type: | Western Union,T/T,Paypal,MoneyGram |

|---|---|

| Min. Order: | 1 Piece/Pieces |

Basic Info

Brand Name: Fce

Shaping Mode: Plastic Injection Mould

Product Material: Plastic

Product: Household Appliance

Product Name: Plastic Injection Mold

Mould Material: Steel/P20/718/Nak80/S316/Aisi H13/Resin/Silicon Rubber

Mould Base: Lkm.Hasco.Dme

Surface Treatment: Texture

Cavity: Single Cavity\ Multiple Cavity

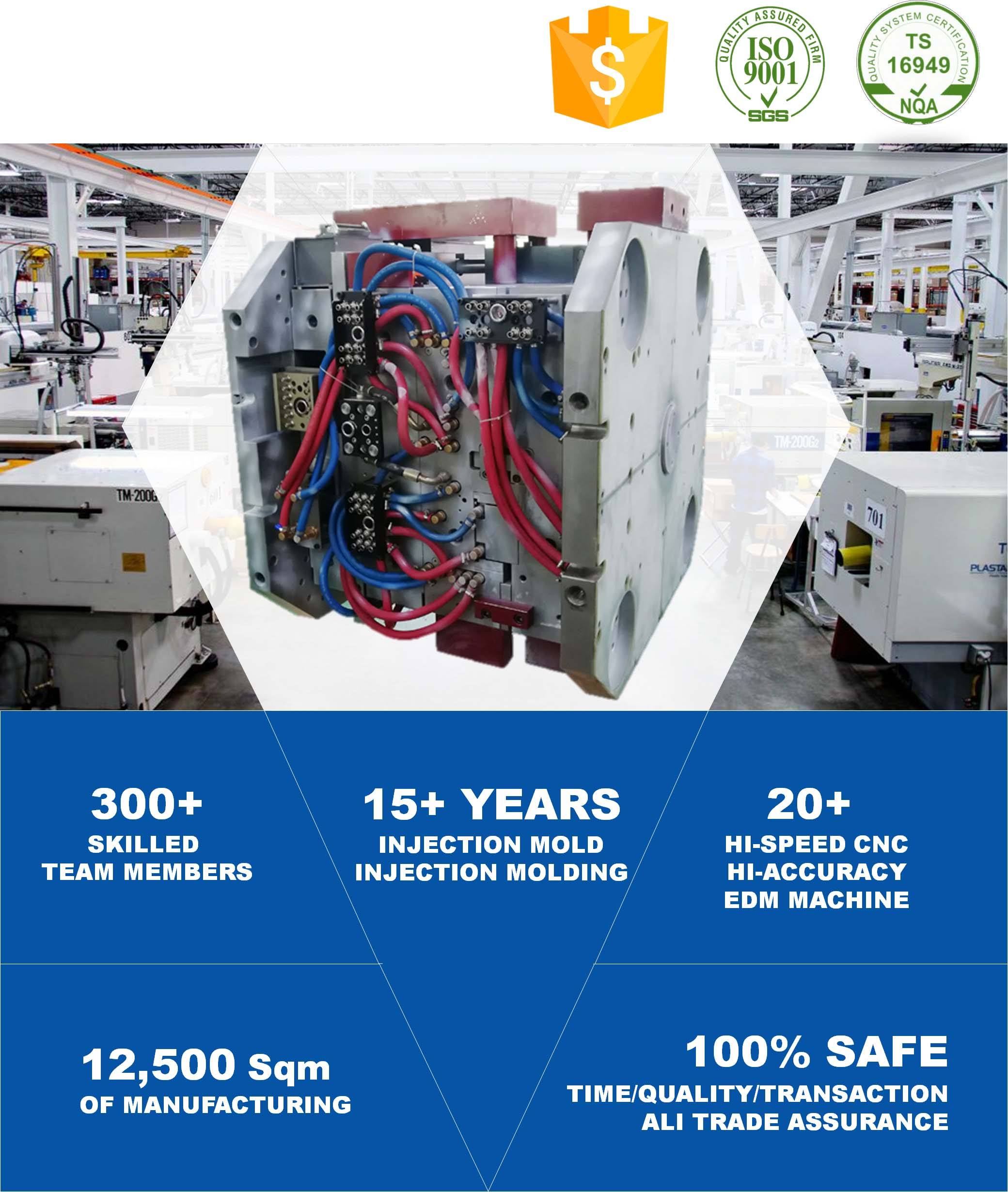

Certification: Iso9001/Ts16949/Qs/Iso14001

Keyword: Plastic Injection Mold Molding Services

Application: Plastic Injection Molding Production

Mould Life: 100k- 500k Shots

Lead Time: 25-35 Days

Place Of Origin: Jiangsu, China

Additional Info

Packaging: Plastic molds packing methods: 1-Surface coated with anticorrosive paint 2-Wrapped with PE film 3-Fixed and sealed by wooden boxes

Transportation: Ocean,Land,Air

Supply Ability: 50 Set/Sets per Month

Port: Shanghai/Ningbo/Shenzhen

Payment Type: Western Union,T/T,Paypal,MoneyGram

Product Description

3D Printing in construction encourages using locally available and natural materials. Such practice could help save transportation, construction, and manufacturing energy, as most local materials are processed and installed using less energy. If traditional materials containing toxic chemicals are replaced with natural materials, the toxicity of building environments may be reduced

Time and cost reduction

A 3D printer can work 24 hours per day, 7 days per week. This means construction projects could potentially be completed much faster, and some low skilled labour costs could be avoided.

Supports unusual designs

One of the most appealing characteristics of 3D printers is their ability to create complex and unusual designs, including ‘one-offs’.

Minimized human errors and improved safety.

Precision Injection Molding and Sheet metal are our core businesses. Delivering injection molding and contract manufacturing in the packaging, consumer appliances, home automation, and automotive sectors etc.

When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

| COMPANY NAME | Suzhou FCE Precision Electronics Co.,Ltd |

| BUSINESS TYPE | Manufacturer |

| MAIN PRODUCTS | Plastic Injection Mold, Prototype tool, Injection Molding Parts, Metal Stamping Die, Stamping Processing for Auto, Consumer Electronics, Appliance, Medical, Houseware… |

| CERTIFICATES | ISO 9001, IATF16949 |

| QAULITY POLICY | Customer-centric, Action concurrent with words |

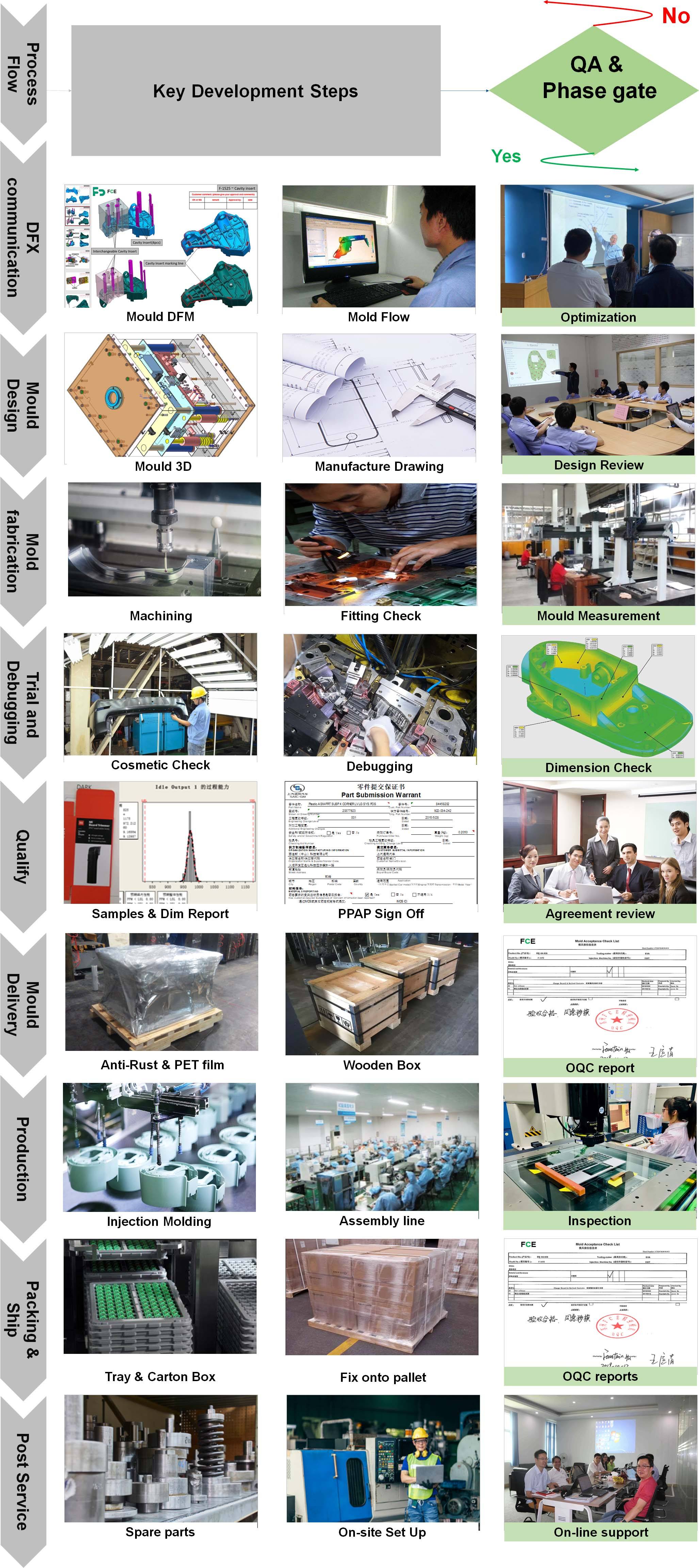

1. Consulting 2. Engineering 3. Prototyping 4. Manufacturing

All in ONE

Where the Good Quality from:

Good Quality Planning, Project Management, Work Procedure, Tracibility

All in our Blood

High precision injection moulding and Sheet Metal are at our core; delivering contract manufacturing in the packaging, consumer appliances, business machines, home automation, life science and automotive sectors. When you choose FCE, you get an expert partner through the entire production cycle, taking your product from concept to reality.

FCE has provided industry-leading injection Molding Services, and we have continued to develop and invest in cutting-edge technologies. Whatever your goals for your component or product, we have the expertise and equipment to deliver. Our specialist capabilities include in-mould labelling and decoration, Multi-k Injection Moulding, liquid silicone rubber, Sheet Metal Processing, Custom Machining, clean room production and more. And because of our global reach, we can cost-effectively source materials and tailored solutions, from concept to reality.

We use our project management skill to create a structured phase-gate process. This establishes your goals and expectations and ensures that you have the oversight and impetus to reach a positive outcome.

The injection Molding, metal stamping, sheet metal processing, machining factories are ceritificated by ISO 9001, IATF16949. Silicone Molding and Injection molding certificated by ISO13485

Product Categories : 3D Printing > Plastic 3d Printing