Molding keyboard Silicone rubber printing Silicone rubber

| Unit Price: | USD 0.3 - 0.8 / Piece/Pieces |

|---|---|

| Payment Type: | L/C,T/T,MoneyGram,PayPal |

| Incoterm: | FOB,EXW,CIF,DDP,DDU,Express Delivery |

Basic Info

Brand: FCE

Brand Name: Fce

Shaping Mode: Plastic Injection Mould

Product Material: Plastic, Rubber, Aluminium, Copper

Product: Household Product, Vehicle Mould, Household Appliance

Processing Technic: Insert Moulding, Imd/Iml, Multi-K, Gas Assistance

Cerifications: Iso9001, Iso14001, Iatf16949, Ohsms18001, Iso13485

2nd Process In House: Pad Printing, Screen Printing, Spray Painting, Assembly

Measurement Equipment: Cmm, Vmm, 3d Scan, Gloss Meter, Colour Meter,

Machine Tonnage: 35ton To 2000ton

Machine Types: Hydraulic, Vertical, Multi-K, Powder Injection

Material Experience: Abs, Gpps, Hips, As, Ms, Pmma, Pc, Pa+Gf, Lcp Etc

Colors Available: Customized Compounded Resin To Pantone Code Or Colour Plaque

Production Working Time: 7x24hrs

Delivery Time: 25days

Forming Method: Silicone Mould, Plastic Injection Mould, Plastic Extrusion Mould, Blowing Mould, Extrusion Mould, Compression Mould

Place Of Origin: Jiangsu, China

Additional Info

Packaging: - Proper packing foam bag/sheet protect the part - Put the part on the PET tray - Pack the tray and products into and carton box - Seal the carton box with tapes - Lay the boxes on the pallet with 8 corners protector - Band the box and pallet together -

Productivity: 5000pcs/week

Transportation: Express,Ocean,Land,Air

Place of Origin: JiangSu

Supply Ability: 100000 Piece/Pieces per Week

Certificate: ISO9001 IATF16949

Port: Shanghai/Ningbo

Payment Type: L/C,T/T,MoneyGram,PayPal

Incoterm: FOB,EXW,CIF,DDP,DDU,Express Delivery

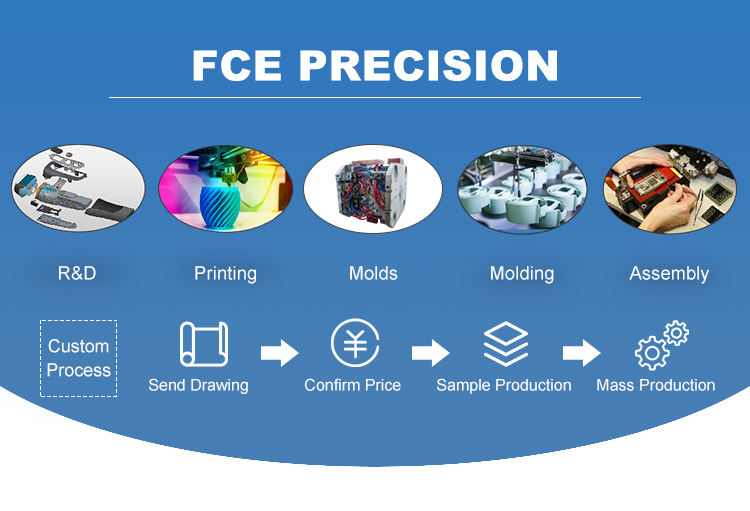

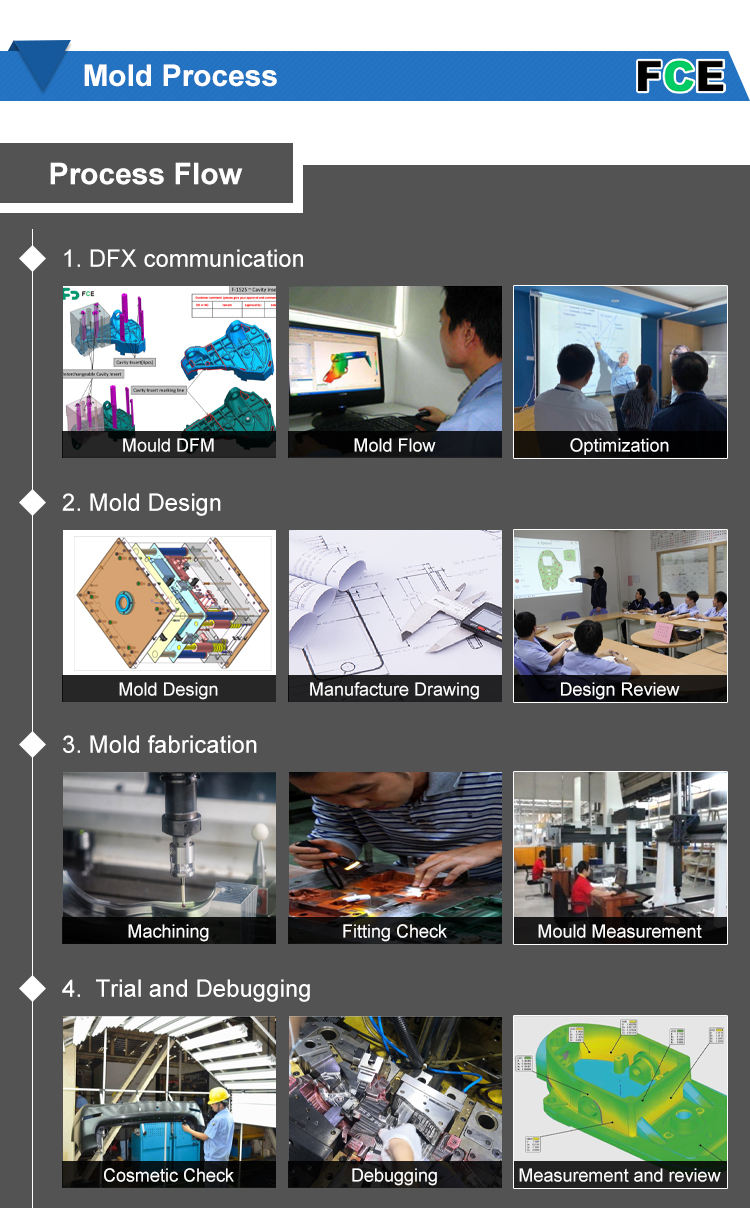

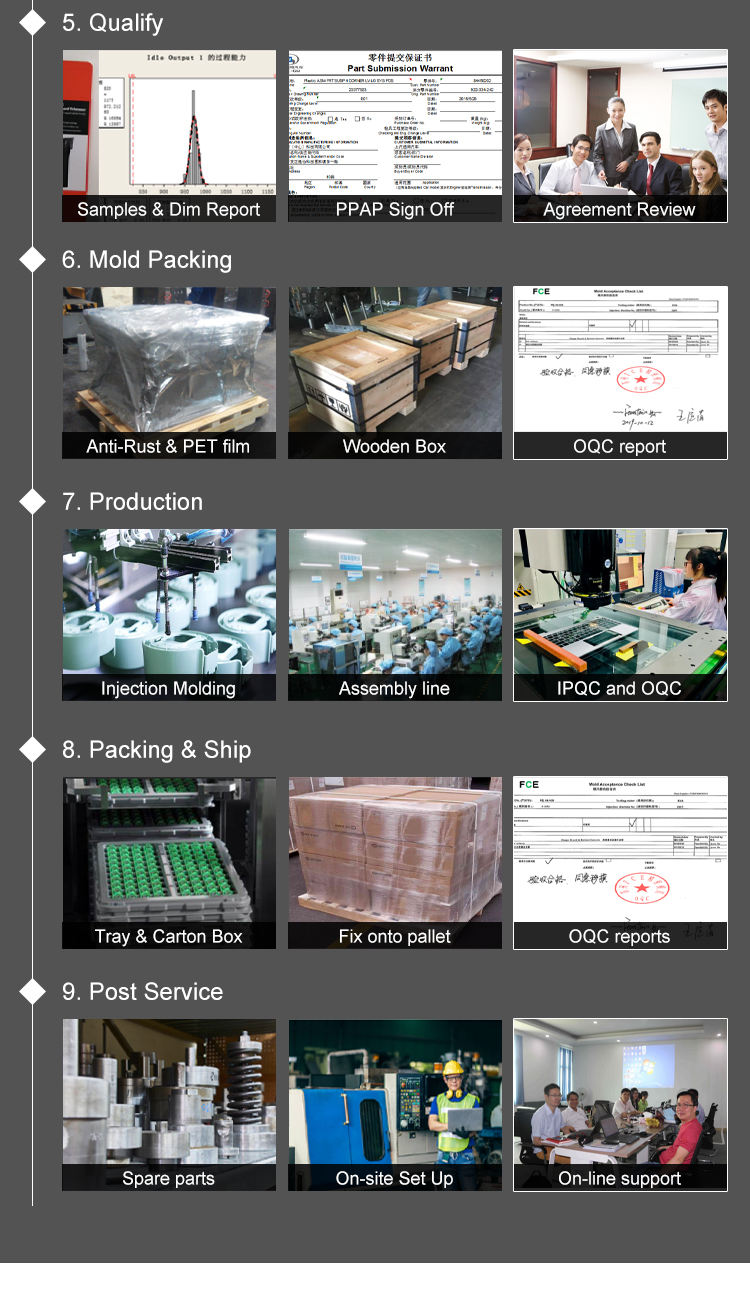

Product Description

In the silicone products industry, to satisfy the needs of the consumers, multicolor series of silica gel products have been belong to compare a product of sell like hot cakes, but for the production process and cost control, a lot of silicone products processing factory in the production of double color or multicolor types of products, will choose a few to save cost and simpler processing method, As we all know, the molding process is the most common processing method in the silicon rubber products industry. For products with relatively single color, multi-color effect can be processed.

Compared with simple point of double color and three color silicone products basically adopts the secondary forming method, this kind of processing methods mainly in the silicone products manufacturers in the production processing, deputy first color body curing, then color division Into the body cavity of a fixed color, in the main body color rubber into the secondary sulfide, make product with a glue process not to big difference, This method also depends on the structure and size of the product in the color system. If the product is too small to put color K, too many colors will affect the efficiency. If you do a simple color, these are no problem

There is a relatively simple method is different colors of bonding synthesis, the silicone gift in the bonding place reserved a certain glue sink, so that in the process of viscose water behind the product can be more firmly bonded, and this way you can choose different colors and hardness and even materials can be bonded.

From the images, you can see the multi color keyboard silicon parts. Different silicon sheet bonded together to get what colors you want and also the silicon part can be pad printed the logo. Since the silicon mold process is much easier, so it can get the lower cost but kinds of products used in these many industrial fields.

So please let me know what can I help you, we have enough capabilities and capacities to meet you.

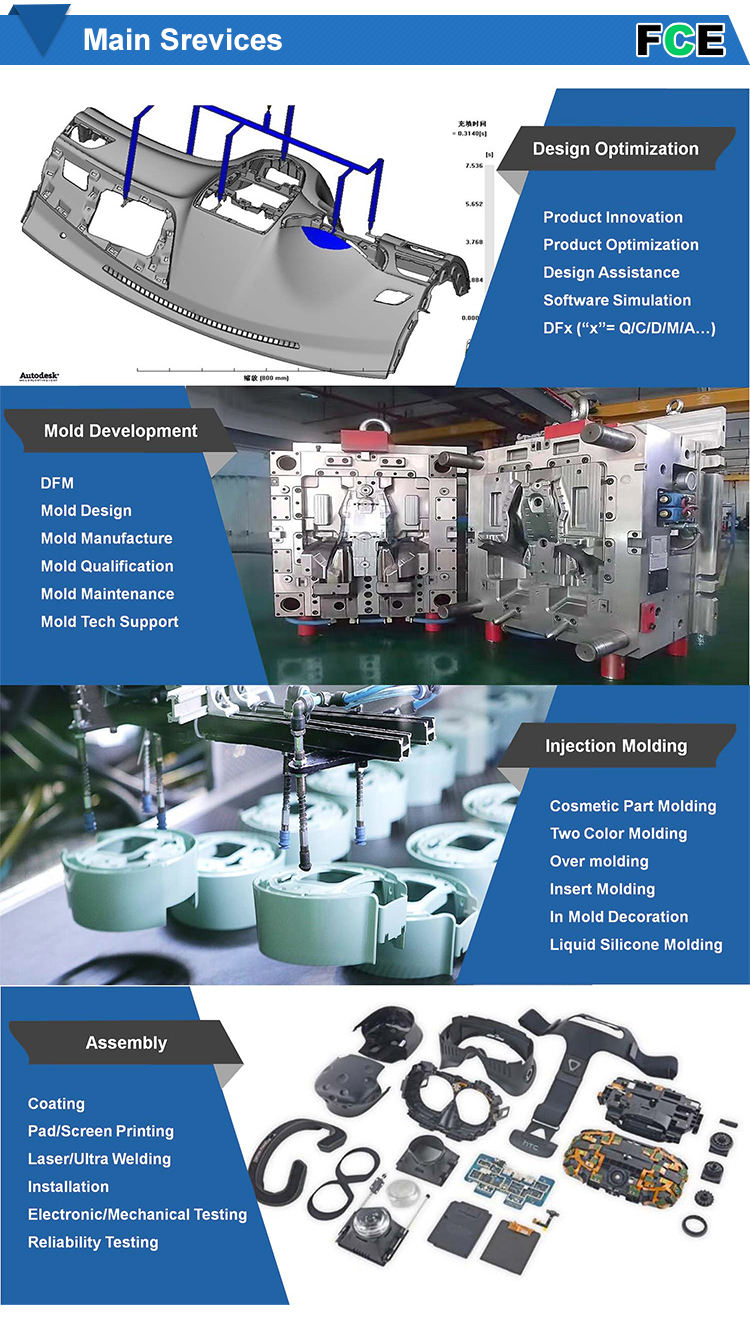

| COMPANY NAME | Suzhou FCE Precision Electronics Co.,Ltd |

| BUSINESS TYPE | Manufacturer |

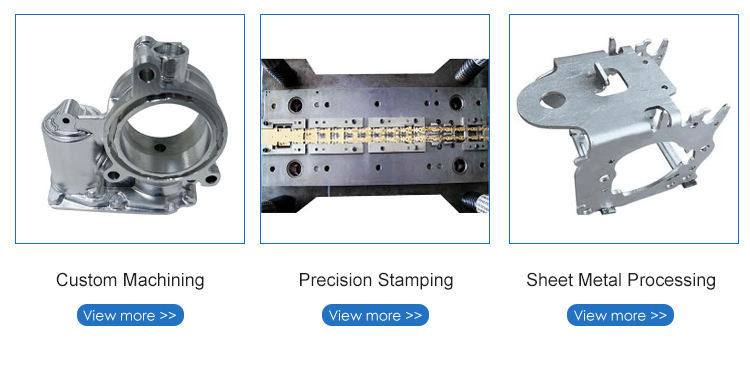

| MAIN PRODUCTS | Plastic Injection Mold, Prototype tool, Injection Molding Parts, Metal Stamping Die, Stamping Processing for Auto, Consumer Electronics, Appliance, Medical, Houseware… |

| MOULD BASE | DME, SD, LKM, HASCO or Goutech Standard for specific parts |

| MOLD MATERIAL | P20/718/738/NAK80/S136/2738/2316/H13... |

| MOLD ACCURACY | +/-0.001mm |

| MOLD LIFE | 50K-1.5Million Shots |

| RUNNER SYSTEM | Hot runner/Cold runner or combined |

| GATE TYPE | Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc. |

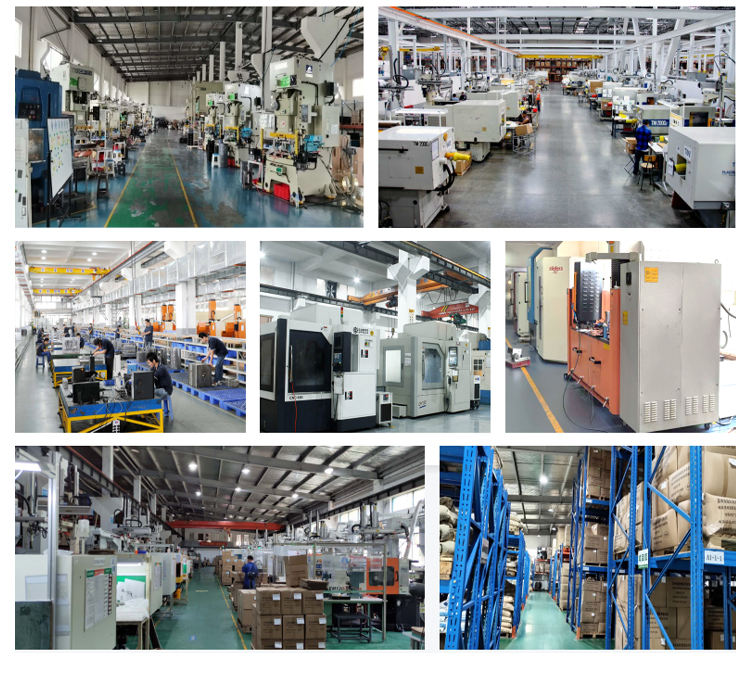

| MOLD EQUIPEMENT | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

| MOLDING FACILITY | 35 TO 650ton Horizontal injection machines, 50 to 160ton Vertical injection machines |

| PLASITC MATERIAL | PA6, PA66, ASA, POM, PPS, ABS, ABS+GF, ABS/PC, POM(Derlin), PP, PE, PC, PMMA(Acrylic), PVC, PEI, PBT, PTFI… |

| SURFACE TREATMETN | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

| CERTIFICATES | ISO 9001, IATF16949 |

| QAULITY POLICY | Customer-centric, Action concurrent with words |

Product Categories : Rubber Moulding > Multi Color Molding