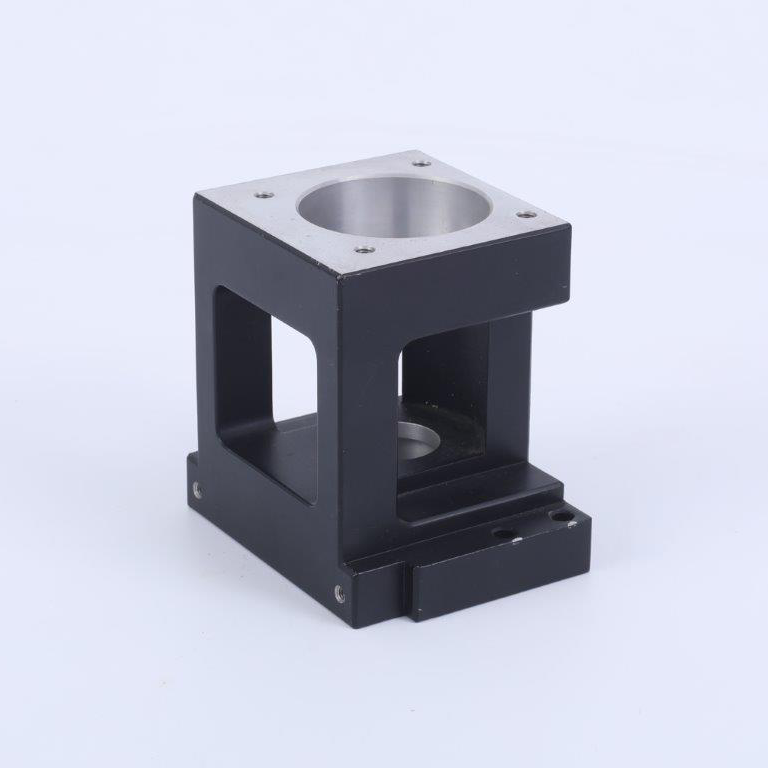

Custom fabrication sheet metal aluminum processing parts

| Unit Price: | 0.5~1.5 USD |

|---|---|

| Payment Type: | L/C,T/T,Paypal,Money Gram |

| Incoterm: | FOB,CIF,EXW,CIP,DDP,DDU,Express Delivery |

| Min. Order: | 1000 Piece/Pieces |

Basic Info

Brand: FCE

Additional Info

Packaging: 1-Wrapped with PE foam 2-Fix the tool into wooden/carton box 3- place the boxes to pallets and fix with belts 4- PE film sailed the pallets

Productivity: 10000pcs/wekk

Transportation: Ocean,Land,Air,Express

Place of Origin: JiangSu

Supply Ability: 1000pcs/week

Certificate: ISO9001 IATF16949

Port: Shanghai/Ningbo

Payment Type: L/C,T/T,Paypal,Money Gram

Incoterm: FOB,CIF,EXW,CIP,DDP,DDU,Express Delivery

Product Description

CNC Machining is a subtractive manufacturing process that uses rotating computer-controlled cutting tools like drills, end mills, and turning tools to remove material from a solid block of material, thereby shaping the part.

Digital design files direct the CNC machines how to cut the block (also known as the “workpiece”) and multiple machines can use the same design file at the same time, which greatly increases the speed of the production process.

CNC machining is a viable option for manufacturing parts with a range of materials, from plastic and metal to wood, fiberglass, and more.

Surface finishes for CNC machined parts

CNC machining can produce parts with tight tolerances and fine detail from a variety of metal or plastic materials.

As Machined

The finish option with the quickest turnaround. parts have minor visible tool marks and potentially sharp edges and burrs, which can be removed upon request. The standard as -machined surface roughness (Ra) is 3.2 μm. Surface finish requirements can be increased to 1.6, 0.8 and 0.4 μm.

Bead Blasting

Bead blasting adds a uniform matte or satin surface finish on a machined part, removing the tool marks. Mainly for visual purposes.

Anodized (Type II Or Type III)

Type II adds a corrosion resistant, ceramic layer to the surface of the machined part. Can be dyed to different colors – clear, black, red, and gold are the most common. It is usually associated with aluminum and Titanium.

Type III adds a wear and corrosion resistant ceramic layer to the surface of the part. It is thicker and Offers greater protection than Type II. Available only for Aluminum and Titanium.

Powder Coating

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. Has a higher impact resistance compared to anodizing. Large range of colors available. Can be applied to any metal.

Electroplating

It is a process that uses an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode. The coating film will help to prevent corrosion and improve wear resistance, conductivity, reflection, and cosmetic appearance.

Product Details

Product Details Material Available Aluminum Stainless Steel Brass Copper Plastic Iron AL6061 SS201 C35600 C11000 POM 20# AL6063 SS301 C36000 C12000 Peek 45# AL6082 SS303 C37700 C12200 PMMA Q235 AL7075 SS304 C37000 C10100 ABS Q345B AL2024 SS316 C37100 … Delrin Q345B AL5052 SS416 C28000 Nylon 1214/1215 etc etc C26000 PVC 12L14 … … C24000 PP Carbon steel ... ... Surface Treatment As machined All metals Polished All metals+Plastic (e.g aluminum, steel,nylon, ABS) Powder Coated All metals ( e.g aluminum, steel) Brushing All metals (e.g aluminum, steel) Anodized Aluminum and Titanium alloys Electroplated All Metals + plastic (ABS, PC/ABS) Bead Blasted Steel and Aluminum and Titanium alloys Anodized Clear or Color Aluminum and Titanium alloys

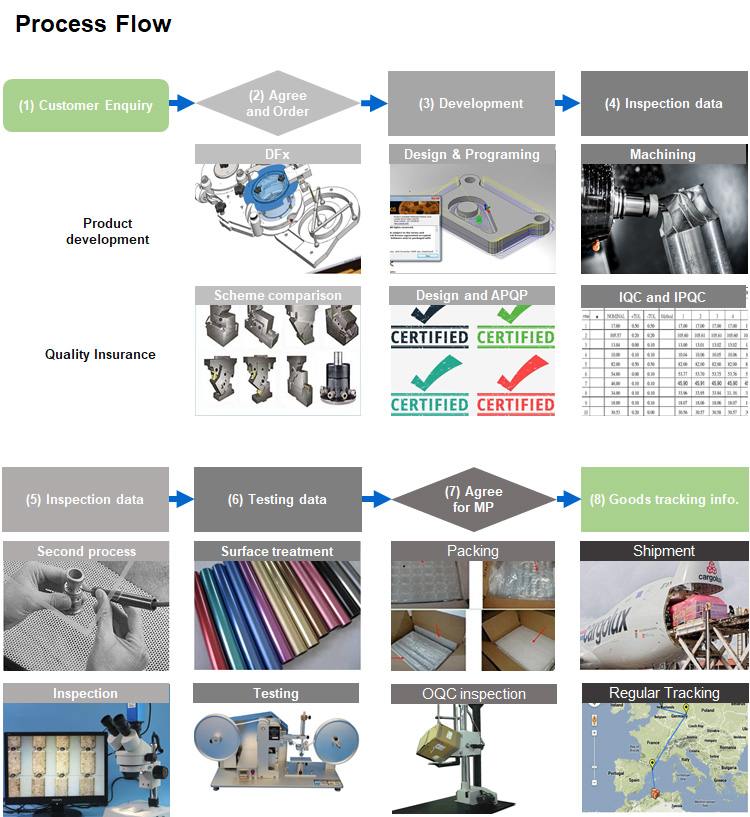

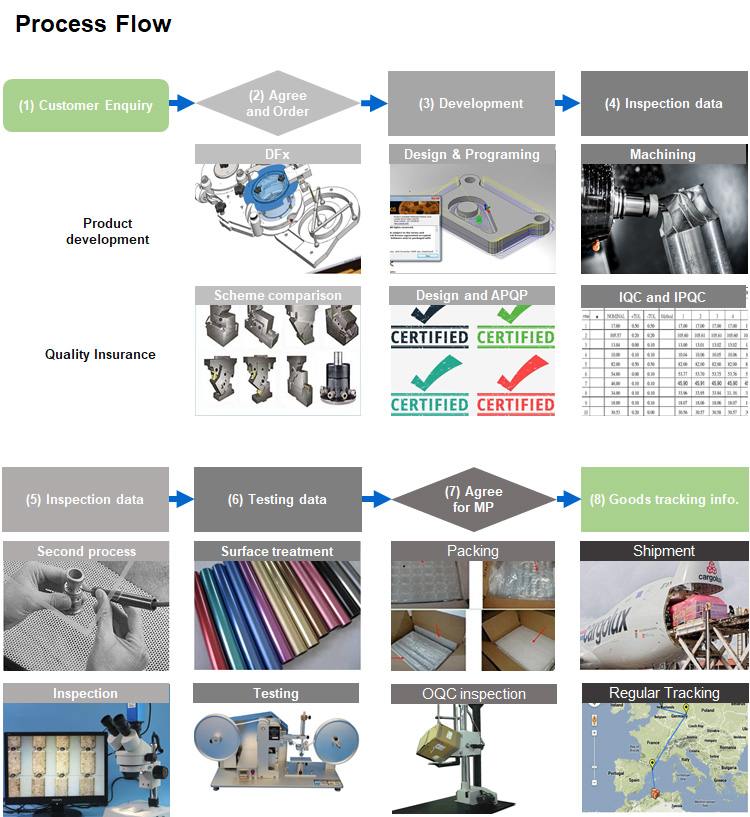

Main Srevices  Process

Process  Company Profile

Company Profile

| Material Available | |||||

| Aluminum | Stainless Steel | Brass | Copper | Plastic | Iron |

| AL6061 | SS201 | C35600 | C11000 | POM | 20# |

| AL6063 | SS301 | C36000 | C12000 | Peek | 45# |

| AL6082 | SS303 | C37700 | C12200 | PMMA | Q235 |

| AL7075 | SS304 | C37000 | C10100 | ABS | Q345B |

| AL2024 | SS316 | C37100 | … | Delrin | Q345B |

| AL5052 | SS416 | C28000 | | Nylon | 1214/1215 |

| etc | etc | C26000 | | PVC | 12L14 |

| … | … | C24000 | | PP | Carbon steel |

| | | ... | | ... | |

| Surface Treatment | |||||

| As machined | All metals | ||||

| Polished | All metals+Plastic (e.g aluminum, steel,nylon, ABS) | ||||

| Powder Coated | All metals ( e.g aluminum, steel) | ||||

| Brushing | All metals (e.g aluminum, steel) | ||||

| Anodized | Aluminum and Titanium alloys | ||||

| Electroplated | All Metals + plastic (ABS, PC/ABS) | ||||

| Bead Blasted | Steel and Aluminum and Titanium alloys | ||||

| Anodized Clear or Color | Aluminum and Titanium alloys | ||||

Suzhou FCE Precision has been specialized in designing and manufacturing metal machining parts for over 15 years. Own a strong engineering team with rich experiences and equipped with many precision manufacturing machines.

Professional to make all kinds of metal parts, like CNC cutting& milling parts, stamping parts, metal sheet parts, assembly unit etc. Our Products cover automotive, Electronic, medical, air, home & office appliance industry.

We are certificated by ISO 9001 and IATF 16949.

CUSTOMER PRAISE

CUSTOMER PRAISE  Our Customers

Our Customers

Certificate

Certificate  Shipping & Delivery

Shipping & Delivery

Professional to make all kinds of metal parts, like CNC cutting& milling parts, stamping parts, metal sheet parts, assembly unit etc. Our Products cover automotive, Electronic, medical, air, home & office appliance industry.

We are certificated by ISO 9001 and IATF 16949.

Product Categories : Machining Service > CNC Machining